The Ultimate Made-in-Canada Conduit Pipe

- Brody Dendekker

- Jun 18

- 3 min read

It’s lightweight, durable, temperature-resilient, and even made in Canada. PowerGuard Flex HDPE pipe is Ontario’s next-generation electrical conduit, the flexible backbone your projects have needed.

PowerGuard Flex is a problem solver engineered for the extremes of Canadian infrastructure. Whether you’re trenching a new duct bank or encasing medium-voltage lines in concrete, PowerGuard Flex is built to stand up to tough conditions and tight deadlines.

Made from high-density polyethylene (HDPE) and manufactured with a minimum cell classification of PE334420C or E (ASTM D3350), this 103 mm (4") flexible conduit withstands Ontario’s harsh cold temperatures of -40°C.

It can also withstand heat up to 82°C and anything that high-voltage projects require. That means your power grid installations don’t get sidelined by temperature swings or the aging brittleness that plagues PVC pipe.

There’s No Comparison Between HDPE and PVC

While Type DBII PVC conduit is a long-time staple among contractors, PowerGuard Flex has the equivalent strength, weighing up to 40% less and many other benefits:

Bends, not breaks

Thanks to its corrugated outer layer, PowerGuard Flex can bend around unexpected ground obstructions with ease, which eliminates the need for manufactured and time-consuming bends.

Shifts with the soil

When frost heave or settling occurs here in Ontario, HDPE’s ductility keeps your system intact, reducing future maintenance costs.

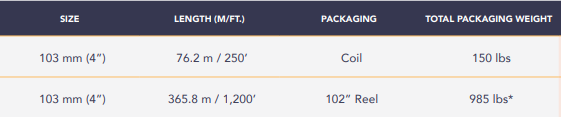

Lengths up to 365.8 m (1,200 ft.)

PowerGuard Flex reduces the number of joints and eliminates the need for excess labour. The lengths arrive ready to use on convenient 300 ft coils and 1,200 ft reels.

Lower installation temperatures

PVC gets brittle in the cold, while HDPE can flex even in frigid Ontario environments.

Conduit Installation Made Easy With PowerGuard Flex

PowerGuard Flex makes installation easy with direct-bury, plow, and concrete encasement options. It’s also CSA C22.2 No. 327 certified for electrical applications, making it the best choice for high-voltage power distribution and electrical duct banks.

Plus, PowerGuard Flex uses SILICORE ULF, an ultra-low friction lining co-extruded inside the conduit wall. This innovation reduces friction by up to 60% compared to standard HDPE, enabling your cables to glide effortlessly over longer distances without the need for messy lubricants.

Top 8 Reasons to Choose PowerGuard Flex

Made in Canada for Ontario’s weather conditions | No cracking, no breakage like you see with PVC |

Cold-weather installations are no problem | Navigates obstacles and tolerates ground shifts |

Resistant to corrosion, acids and chemicals | Lengthy, continuous runs cut down on joints |

Quick and secure couplers eliminate gluing | Environmentally friendlier than PVC with 100% recyclability |

Electrical Conduit Built for Compatibility

If you need to join with other electrical conduit types, PowerGuard Flex connects easily to HDPE, PVC, FRE, and TGS using CSA-certified key lock couplers.

Sandale Ontario’s team can also help you with accessories such as spacers, plugs, end caps, and adapters, which help simplify installation and improve the long-term reliability of conduits.

Who Does PowerGuard Flex Help Most?

Project Managers

Keep your timelines on track. With faster, cleaner cable installations, crews that use PowerGuard Flex can work more efficiently and avoid delays caused by lubricant mess or rework.

Inspectors & Regulators

Trust in a solution that’s fully CSA-certified and built to last. PowerGuard Flex supports safe, code-compliant infrastructure. This is ideal for high-voltage and underground utility applications.

Contractors

Save valuable time on the job site. When you use PowerGuard Flex with SILICORE® ULF ultra-low friction lining, it makes cable pulls up to 60% easier with no messy lubricants.

Engineers & Designers

Our HDPE conduit meets the rigorous standards of CSA C22.2 No. 327, ensuring code compliance, reliability, and long-term performance in your electrical designs.

Utility Providers & Municipalities

Engineered for critical infrastructure, PowerGuard Flex delivers exceptional durability, flexibility, and ease of installation, even in the toughest environments. This is especially true for utility providers like Hydro One and Toronto Hydro!

Distributors & Suppliers

Offer your clients a solution that combines quality, compliance, and contractor-preferred performance.

Ontario’s Smarter Conduit Solution is Now Available

Want to dig deeper into the technical details? Download the PDF here for basic specs, then reach out to Sandale Ontario’s project team to walk you through the design and installation phase.

Remember, PowerGuard Flex is more than just a pipe—it’s a smarter conduit solution for tomorrow’s infrastructure. Whether you’re building a substation, expanding a utility corridor, or installing a high-voltage duct bank, make sure you’re using a conduit that bends, lasts, and performs.