Why Sandale Ontario Recommends HDPE Pipe Systems over PVCO

- Brody Dendekker

- Aug 6

- 5 min read

The materials you choose will make or break the success of your water pipe system. Among the leading piping materials in Ontario today are HDPE (High-Density Polyethylene) and PVCO (Molecularly Oriented Polyvinyl Chloride).

While both are popular non-metal piping options, a closer look at their structural, performance and installation reveals that HDPE is the better solution.

At Sandale Ontario, we have decades of experience supplying HDPE systems across the province and have witnessed firsthand how HDPE consistently outperforms PVCO in real-world conditions, from water transmission to mining and stormwater systems.

What is PVCO?

It is a high-performance type of plastic pipe used primarily for pressurized water systems, such as municipal water distribution and irrigation.

PVCO is made by taking standard PVC (polyvinyl chloride) pipe and stretching it under specific conditions. This orientation process improves its strength and durability while reducing the amount of material needed.

A higher-strength plastic pipe sounds great, but does this process make a solution better than HDPE? Let’s take a closer look.

HDPE vs. PVCO Pipe Technical Comparison Table

Feature / Property | HDPE (High-Density Polyethylene) | PVCO (Molecularly Oriented PVC) |

Flexibility | Highly flexible; ideal for curved paths and ground shifts in freeze-thaw environments | Even more rigid than standard PVC |

Jointing Method | Heat fusion or electrofusion (monolithic, leak-free) | Gasketed bell-and-spigot joints (potential for leaks) |

Trenchless Compatibility | Perfect for HDD, slip-lining, pipe bursting | Not suitable due to stiffness and joint type |

Installation Time | Rapid fusion methods; longer lengths reduce downtime | Shorter lengths, more joints, more manual handling |

Corrosion Resistance | 100% resistant to corrosion and chemical attack | Resistant to corrosion, but less tolerant of aggressive soils |

Fatigue Resistance | High. Endures pressure surges, vibration, and temperature swings | Low. Microfractures can occur |

Design Life | 100+ years | Typically 50 years |

Environmental Impact | Fully recyclable; low lifecycle emissions | Non-recyclable in most cases; manufacturing is energy-intensive |

Burst Strength vs. Long-Term Strength | Moderate burst, excellent long-term performance | High burst, poor fatigue resistance |

Standard Sizes Available | Wide range up to 65” diameter | Smaller diameter limitations; pressure class focused |

Flexibility That Adapts to Ontario’s Challenging Terrain

One of the greatest engineering benefits of HDPE is its flexibility. Whether it’s winding under a roadway or adjusting to frost heave in Northern Ontario, HDPE can deflect and return to shape without cracking or splitting.

PVCO, on the other hand, is a rigid material that cannot tolerate movement as well. This makes it high-risk in areas with shifting soils, seismic activity, or extreme freeze-thaw cycles, which are common throughout Canada.

“HDPE’s flexibility allows us to trench less, curve more, and install faster, without compromising pipe integrity.”

-One of Sandale Ontario’s customers

Plastic Pipe Joints That Never Leak

HDPE piping systems are fused using heat, creating a monolithic system that’s effectively one continuous pipe. There are no gaskets, no joints to slip or leak, and no metal clamps that can corrode.

PVCO uses old-fashioned bell-and-spigot joints with rubber gaskets. While these may be faster to connect initially, they’re vulnerable to leaks due to settling, vibration or joint movement, and they can allow tree roots or contaminants to enter the system.

A little more time on installation means far fewer issues years later.

Trenchless Installation Saves Time and Money

HDPE is the undisputed champion of trenchless technology, including:

These methods minimize surface disruption, reduce labour, avoid road closures and cut project costs. PVCO is incompatible with trenchless methods due to its brittleness and limited joint strength under tensile stress.

It takes longer and costs more money with PVCO.

Cold Weather & Freeze-Thaw Resilience

When temperatures drop, HDPE keeps performing. Its ability to expand and contractor helps it to remain shatter-resistant down to -40°C, making it ideal for Canadian climates.

PVCO, on the other hand, becomes brittle in cold weather (below -10°C) and may fracture under impact or pressure changes.

This becomes critical during:

Winter installation

Emergency repairs

Sudden temperature shifts

Long-Term Value That Outpaces Upfront Costs

It’s true that PVCO can appear cheaper up front, but the long-term economics favour HDPE.

Here’s why:

Cost Factor | PVCO | HDPE |

Initial Material Cost | Slightly lower | Slightly higher |

Installation Labour | Higher due to joint complexity | Lower with fusion & trenchless |

Leak/Maintenance Risk | Moderate–High | Very low |

Longevity | ~50 years | 100+ years |

Total Lifecycle Cost | Higher | Lower |

According to Piedmont Plastics:

Even though HDPE is more durable and flexible than PVC and lasts longer without degradation, it costs a little more than its competition. However, when considering cost-effectiveness, you must look beyond the purchase price.

With HDPE, you don’t have to use cement to join pieces. Because it is joined with heat, the process requires minimal wait time. As a result, you do not have to wait for the cement to cure, and you can use your new pipes more quickly.

HDPE is also more cost-effective to transport. You do not have to protect it from sunlight as you do with PVC because it is UV resistant. This combination of less cost and time to install and less cost for transportation helps counter the higher purchase cost.

Finally, HDPE will last longer than PVC in most applications. Not having to replace and repair pipes as often adds up to major cost savings. In light of these factors, HDPE is typically the more cost-effective option.

Environmentally Friendly & Future-Ready

Sustainability is increasingly important in infrastructure decisions. HDPE leads here, too:

100% recyclable;

Lower greenhouse gas emissions during manufacturing;

No toxic chemicals leaching into the soil;

Safe for potable water; and

Proven track record in green building certifications. (e.g., LEED)

PVCO is manufactured using PVC manufacturing processes followed by energy-intensive molecular orientation and is difficult to recycle due to its chemical composition. (Many municipal recycling centres in Ontario don’t accept PVC because of contamination concerns and its complex reprocessing process.)

Proven in Demanding Applications Across Ontario

Sandale Ontario has supplied HDPE systems for:

Water mains and municipal distribution

Stormwater and drainage

Mining and slurry transport

Agricultural irrigation

Gas distribution

Industrial chemical transport

Renewable energy and geothermal systems

Each project benefits from custom fabrication, field support, and long-term confidence. PVCO simply cannot meet this range of application demands.

HDPE is Ontario’s Smartest Pipe Solution

While PVCO may offer limited benefits in small-scale or straight-run installations, HDPE dominates in strength, flexibility, cost environmental impact and longevity.

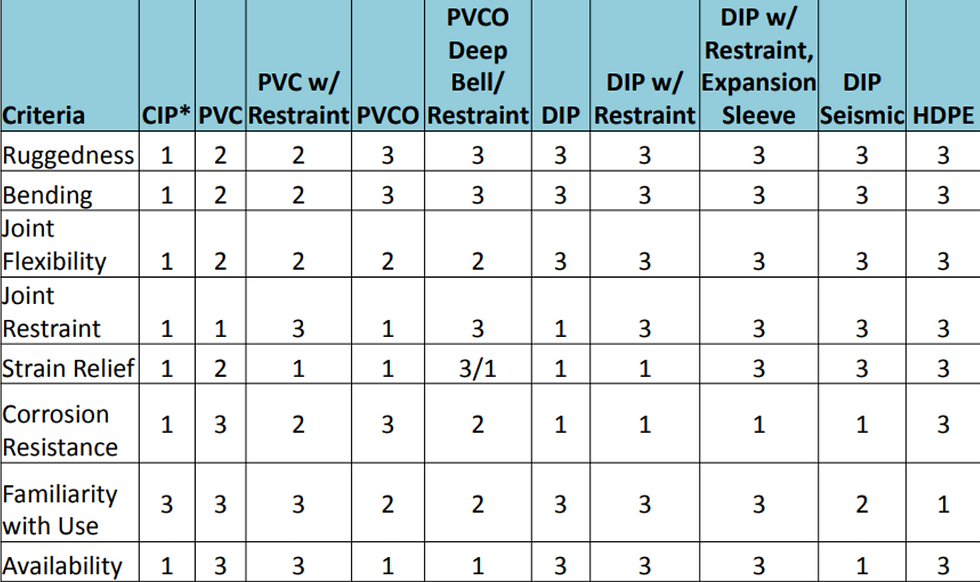

This chart issued by the Plastic Pipe Institute shows just how excellent HDPE is compared to other plastic pipes.

At Sandale Ontario, we don’t just believe in HDPE, we back it with full-service support, design assistance, and fusion solutions that get the job done faster and smarter.

Whether you’re building a municipal water main, replacing stormwater infrastructure, or running utility corridors across challenging terrain, Sandale Ontario is your HDPE partner from spec to install.

Take the Next Step:

Call us today at 519-754-1366.

Email us at sales@sandale.ca to book a free consult.